What is the process of opening an injection mold?

- san Su

- Feb 28

- 2 min read

What is the process of opening an injection mold?

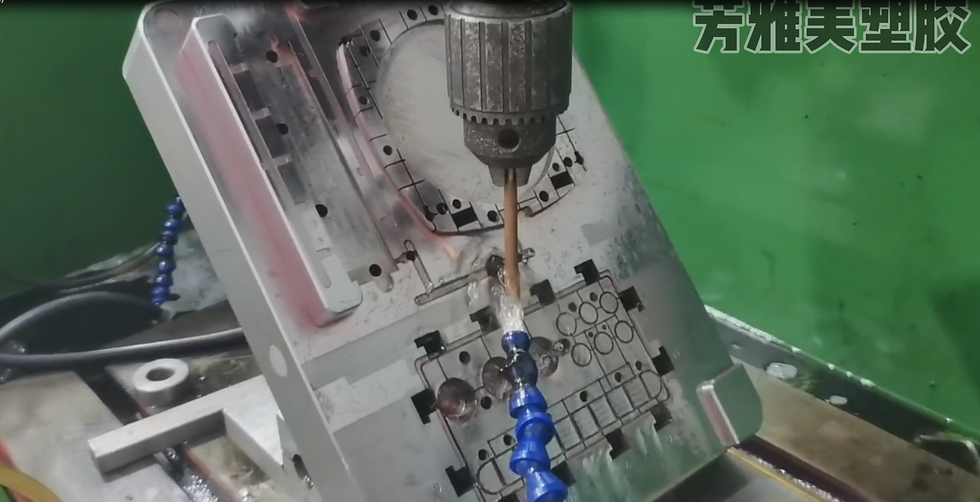

First, the designer needs to design the product and convert it into an accurate 3D CAD model and then into a CAM program for processing and production on the injection molding machine. These programs can perform different actions as needed, such as nozzle movement, plastic molding, part ejection, etc.

The mold is usually made of different types of steel materials and requires precise measurement and cutting to ensure the accuracy and quality of each plastic part.

Once the mold is ready, the plastic can be injected to test the mold. This process includes the following steps:

1. Put plastic pellets into the hopper of the injection molding machine.

2. The injection molding machine heats and pressurizes the plastic to make it liquid.

3. The liquid plastic is sprayed into the mold and allowed to cool and solidify.

4. Open the mold and eject the plastic part.

5. Repeat the above steps until the required number of plastic parts are produced.

After the product is completed, it needs to be carefully inspected and tested to ensure that the product meets the design specifications. If any defects need to be repaired, the mold can be repaired, or the parts can be repaired or re-injected.

In general, the process of plastic injection molding is a very complicated process. Whether it is electronic product shell molds, plastic toy molds, daily necessities molds, home appliance molds, automobile molds, medical accessories molds or mobile phone cases, injection plastic production is an indispensable part of their manufacturing process.

Shenzhen Fangya Plastic Products Co., Ltd. is a factory that can provide customers with product structure design, plastic mold development, and injection molding processing. Experienced engineers will avoid problems in the early product design and help the product to be mass-produced and cost-controlled as soon as possible.

Comments