One-stop/mold/injection molding/packaging manufacturer

ISO9001 factory | Design new products | 7-day proofing | Quality assurance | MOQ:5000pcs

whatsapp:+08615217056630

Company profile

-

Shenzhen Fang Yamei Plastic Products Co., Ltd. was established in 2009. The company strictly follows the ISO9001 quality management system certification requirements to complete all work to ensure product quality. The products are exported to many countries overseas.

-

-

Injection Molding Department: mold manufacturing, plastic parts production and processing, electronic plastic accessories, toy plastic accessories, daily household plastic accessories, medical precision parts, electrical housing accessories, etc.

-

-

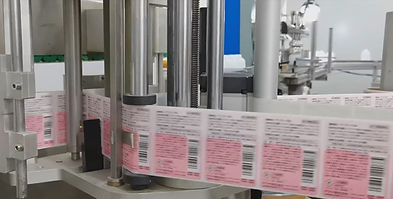

Blow Molding Department: can be customized for personal care products (shampoo bottles, shower gel bottles), cosmetics (skin care bottles, lotion bottles, vacuum lotion bottles), chemical bottles, medicine bottles, etc., and equipped with plastic pumps, plastic caps, nozzles, foam pumps and other accessories.

-

-

Fang Yamei Plastic is a manufacturer integrating mold manufacturing, injection molding, blow molding, processing, silk screen printing, and labeling. We have won the recognition and support of domestic and foreign customers with our professional, responsible, honest and punctual service attitude.

About product customization

-

We can make brand new molds for various types of plastic bottles according to the drawings provided by customers.

-

We can also make various injection molds according to the 3D drawings provided by customers.

-

The mold maker has more than 15 years of experience in mold making.

-

We can customize the color, pump head or cover, silk screen or labeling according to the requirements.

-

MOQ: 5,000 pcs

-

Product delivery time: 25 -35days

-

Injection mold production time: 30-50 days

-

Blow mold production time: 18 days

Product production scene

ISO9001 international quality system certification, choose us for more quality assurance

The factory was established in 2009 with a professional management team

Successful Cases

-

Professionally upgraded packaging for customers’ brands and won market share.

-

After the new packaging was launched, product sales soared