How are plastic products made

- san Su

- Jan 4

- 2 min read

How are plastic products made

Have you ever used plastic products? Do you know how plastic products are made?

Behind plastic products lies the complex process of injection molding. Injection molding is a method of manufacturing plastic products, and its process can be roughly divided into the following five stages

1. Plasticization stage:

Plastic powder or granules gradually melt into a plastic melt with a certain fluidity after being heated, compacted and mixed in the injection molding machine. This stage is the basis of injection molding, and the quality of the plastic melt directly affects the quality of the final product.

2. Injection stage:

During the injection stage, the screw of the injection molding machine moves forward, and the plastic melt stored at the front end of the barrel is injected into the closed mold cavity through the nozzle and the pouring system of the mold. The injection stage needs to control parameters such as injection speed, injection pressure and melt temperature to ensure that the melt can fill the mold cavity.

3. Pressure holding stage:

When the mold cavity is filled with melt, the pressure holding system of the injection machine starts to work, applying a certain pressure to the melt in the mold cavity to compact it and compensate for shrinkage. This stage is very important for eliminating internal defects of products and improving the density and dimensional stability of products.

4. Cooling stage:

After the pressure holding stage, the melt in the mold cavity begins to cool and solidify. The temperature and cooling time of the mold need to be controlled during the cooling stage to ensure that the product can be fully solidified and has the required shape and dimensional accuracy.

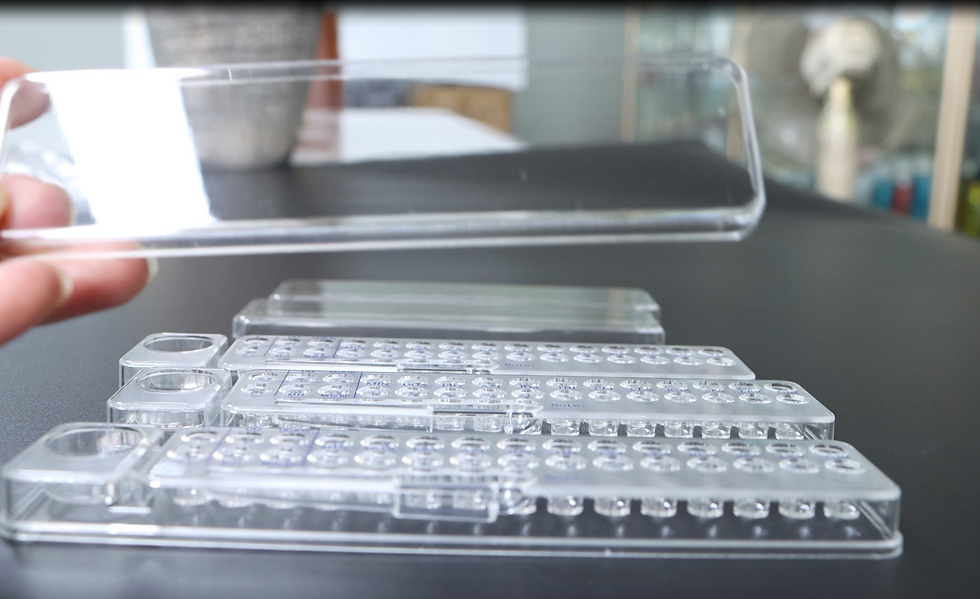

Medical Test Card

5. Demolding stage:

When the product is cooled to a sufficient hardness, the mold opens and the product is ejected from the mold through the ejection mechanism. At this stage, attention should be paid to the control of the ejection force to avoid deformation or damage of the product during the demolding process.

Comments